Why Commercial Sandblasting Is An Effective Option? Pros and Cons of Commercial Sandblasting

Sandblasting is a process that is used to remove dirt, debris, and old paint from a surface. It is an efficient method to make a surface smooth and clean. Professionals who do sandblasting use a sandblaster to spray pressurized sand particles on a surface and make it leveled and even.

This process utilizes the abrasive properties of sand to give a perfect finish to any object. Sand is naturally gritty and rough which allows it to create friction and remove an unwanted layer of dirt and paint from a surface.

Sandblasting is a process that is used diversely in industrial and commercial fields. In this blog, we will discuss briefly why commercial sandblasting is an easy, efficient, and effective option.

Advantages of Commercial Sandblasting

There are many pros to commercial sandblasting. We have listed some of these benefits below

1. Easy Clean

If you are someone who has been working in the commercial sector for a while, you must know that it requires you to clean old paint and debris from huge surfaces. With sandblasting, the job is done without any hassle. Commercial sandblasting helps you clean metal, concrete, and wood. You can also remove grease, oil, and paint that is almost impossible to get off an object or equipment.

2. Time Efficient

Another reason why commercial sandblasting is an effective option is that it is extremely time-efficient. It can do the job in no time. Commercial sandblasting has replaced the use of sandpapers and hand sanding which takes a lot more time and effort. Sandblasting is quicker and also gives a quality finish.

3. Useful Priming Tool

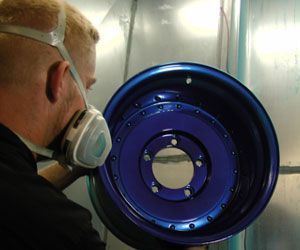

Commercial sandblasting is not only used for cleaning purposes, it is frequently used to prime commercial surfaces for repainting. You can use sandblasting to remove paint from a surface and close cracks to make it smoother. Sandblasting removes ugly crevices and makes the surface smooth and primed. It is easier to apply paint on a smooth surface, this is the reason why sandblasting can improve the results of commercial repainting.

4. Non-Toxic Process

Many cleaning processes require several steps to complete and involve the use of harsh chemicals that are not safe to breathe in. However, commercial sandblasting is a process that uses non-toxic materials that are not hazardous to health. These materials are safe to use on your equipment. Industry equipment is strong and can endure sandblasting. Commercial sandblasting is very commonly used to increase the life of industrial equipment.

5. Removes Rust and Dust

Be it a commercial kitchen or an industrial business, it is very common for commercial equipment to accumulate rust. Rust and corrosion can make your equipment look old and beaten. Moreover, it can reduce the life of your business tools. Sandblasting is a great and easy option to restore your rusty equipment to its life.

Sandblasting, when done by professionals, can make your life easier and better. It is a process that is becoming increasingly popular in the commercial sector for its time-effective and quality-efficient results.

The post Why Commercial Sandblasting Is An Effective Option? Pros and Cons of Commercial Sandblasting appeared first on Full Blown Coatings.