All You Need To Know About Powder Coating Ovens

Powder coating is a process that protects materials from rust, dust, and other environmental factors by creating a protective resin finish. Once the granulated powder of thermoset and thermoplastic is sprayed on the surface, it needs to go into the powder coating oven to cure. Curing the coated powder makes the pigment and plastic adhere firmly to the metal surface and gives a smooth incomparable finish.

Powder coating ovens are required to sustain the temperature of 450 degrees Fahrenheit and must be large enough to contain all the powder-coated objects. One great thing about powder coating ovens is that they don’t require the use of solvents which means that they are eco-friendly as well.

In this blog we will discuss everything that you need to know about powder coating ovens and how do they work?

How Do Powder Coating Ovens Work?

Once the substrate is coated, it is cured by the powder coating oven so that the powder can adhere to the metal surface extremely firmly. The heat melts the pigments and resin particles together to make a durable and long-lasting layer of paint. This infused layer of paint looks extremely smooth and gives a flawless finish.

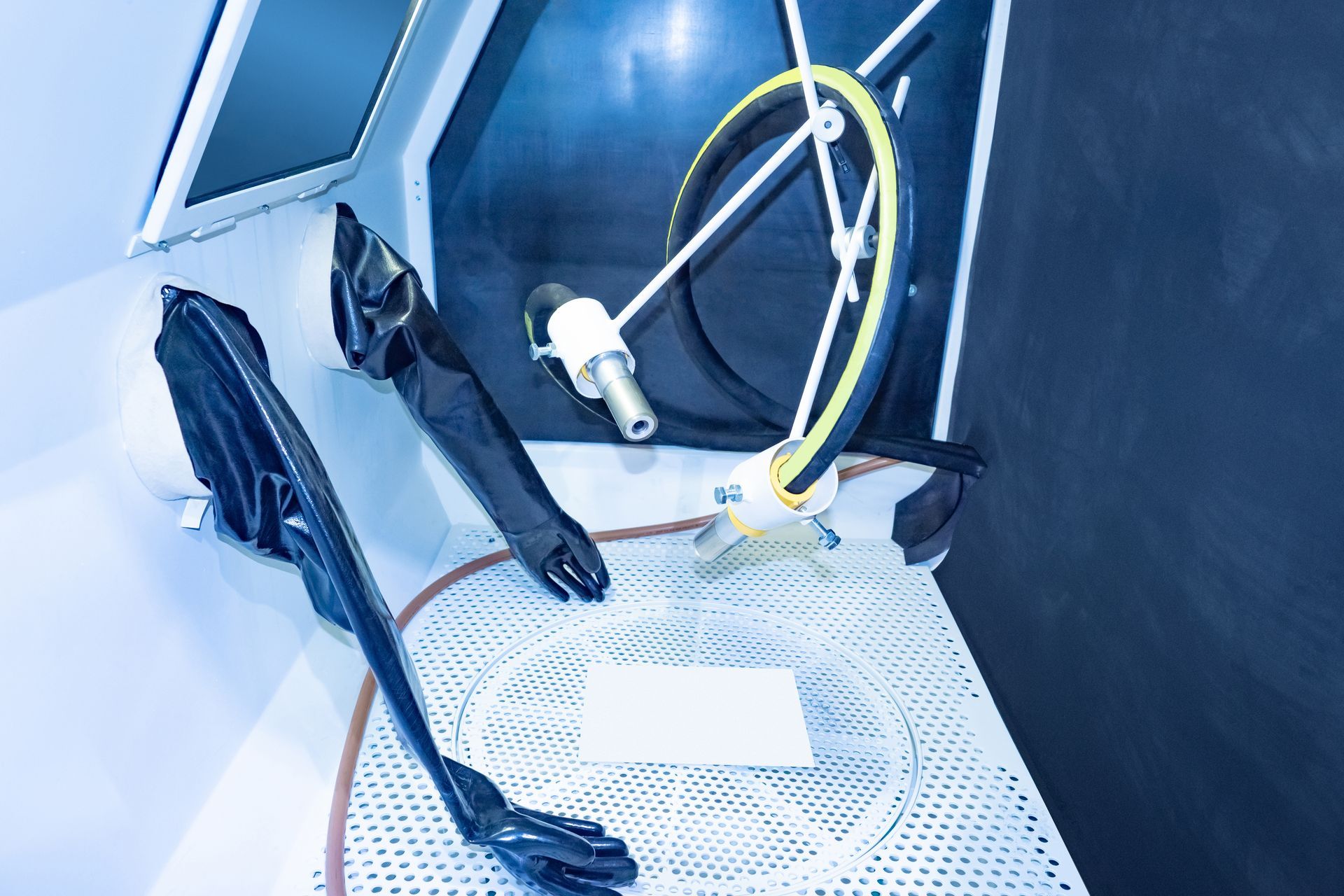

Powder coating ovens use a determined amount of heat to make the powder adhere to the surface. Specialist ovens are used for this purpose. The coating should not be in direct contact with the heating element and the heating element should not be extremely close to the powder coating or it will burn the coating.

Convection heating is used to direct the heat into the entire object. The powder coating oven must contain a heating coil to direct infrared heat through the object. A determined temperature is used to cure the object and a timer is employed in a powder coating oven to make sure that the coating is not burned. Using a controlled amount of time and temperature is very important to ensure that the powder will form a solid film of plastic around the object to protect it from environmental influence.

Since powder coating is a process that has diverse applications, one of its most important features is its volumetric capacity. Powder coating is very commonly used in the automotive industry to powder coat critical components and make sure that they do not warp from the consistent use which means that powder coating ovens need to be big enough to contain larger components. They must also have a greater control system to ensure even heating throughout the curing chamber.

This is the reason why an integrated control system is very valuable for a powder coating oven. These systems include airflow rotation and highly precise temperature control to easily alter the conditions of the curing chamber.

The post All You Need To Know About Powder Coating Ovens appeared first on Full Blown Coatings.