Sandblasting Process; How Does It Work?

Sandblasting is a surface finishing process that uses the ability of sand grits to smooth out any surface and get rid of the uneven texture and flaws. It is used on both industrial and creative levels. Sandblasting is also most commonly referred to as abrasive blasting. In this blog, we will explain to you how sandblasting works and what is the process?

How Does Sandblasting Works?

From smoothing and removing old paint to etching and engraving, sandblasting is a process that is used in many professions and fields. Through this process, a surface is eroded with the help of a concentrated stream of extremely fine sand. It is not a great discovery that sand is rough and gritty by its nature. When the sand particles strike a surface, it is able to wear off any excess material and make the surface more polished and even- all thanks to the abrasive properties of sand.

Detailed Process of Sandblasting

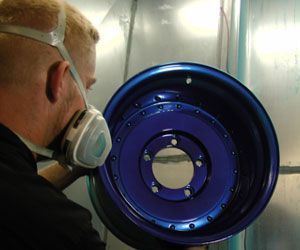

As we mentioned earlier, sandblasting requires the use of power machines- typically a sandblaster and an air compressor.

The very first step that needs to be done to successfully “blast” a surface is to pour the sand into the sand sandblasting machine. There is a section at the top of the sandblasting machine through which the sand goes in. After you pour in the sand, your sand blasting machine is then connected to a conventional air compressor.

When you activate the air compressor, it propels the sand out of the sandblaster through a handheld nozzle. Depending upon the surface that you are sandblasting the pressure of the sand can be set from 50 to 130 pounds per square inch (PSI). When a surface is blasted with this sand, it grits a surface smooth. Sandblasting is also used to remove old paints from a surface or even roughen up a smooth surface. The use of sandblasting is very versatile; it can be used to creatively shape an object or to get rid of uneven surface texture.

For instance, concrete is often blasted with fine pressurized sand. After the concrete is poured and allowed to dry, you are left with a bumpy and uneven surface. This is why it is treated with sandblasting. It removes some of the excess material from the top making it even and leveled.

The reason why sandblasting process has applications in diverse fields is that it is an efficient and quick process. Sandblasting has successfully replaced sandpapers and eliminated the need to hand sand every surface. This process saves a lot of time, effort, and the mess of hand sanding.

The post Sandblasting Process; How Does It Work? appeared first on Full Blown Coatings.