Why to Use Sandblasting?

Sandblasting is a common process in metalwork and fabrication jobs. Despite its name, you can use more than just sand. Before starting a powder coating project, it is typical for a company to use it to remove existing paint and aberrations from the material. While there are other options to do this, there are several key reasons why sandblasting is one of the most popular methods…

Flexible Medium Options

Even though it’s called “sandblasting”, you can actually use lots of types of “mediums” to blast metal clean. This includes steel grit, broken glass beads, steel wires, and walnut shells, among many other options. Each of these options has different benefits. For example, nut shells are an excellent biodegradable option, but might not be as reusable in other types of medium.

Reusable Mediums

When you blast metal, it uses a great amount of medium, which is the abrasive material you are using to get rid of paint and whatever else is on the surface. The process of sandblasting enables you to reuse whichever medium you chose to use. These mediums can be used multiple times, which helps make sandblasting an economic option.

Convenience

When you try to remove paint or clean a metal surface manually, it is an incredibly labor-intensive process, taking hours of time and effort. Sandblasting is a far more convenient solution, allowing for a quicker removal time that takes far less physical exertion from the individual.

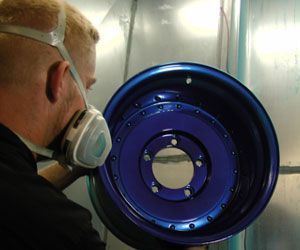

Perfect for Paint Preparation

Even if you aren’t going to powder coat the metal surface, sandblasting can be a necessary first step to prepare for a paint job. Sandblasting is highly effective at getting rid of old paint that is stuck on a metal surface. Other paint removal methods can potentially leave particles behind that will lessen the perfection of the new paint.

The post Why to Use Sandblasting? appeared first on Full Blown Coatings.