What is the life expectancy of a coating?

The lifespan of a coating varies depending on the type of coating, the surface it’s applied to, and the conditions it’s exposed to. Here’s a simple breakdown of what you can generally expect:

Powder Coatings

- How Long They Last: Around 15–20 years, sometimes longer if conditions are right.

- What Makes a Difference: How well the surface was prepped, how the coating was applied, and the kind of environment it’s in. For example, too much sun or moisture can shorten its life.

- How to Help It Last: Keep it clean and check it regularly for any signs of wear.

Paint Coatings

- How Long They Last: About 5–10 years, depending on the paint and the surface.

- What Makes a Difference: The type of material underneath, plus exposure to things like weather, chemicals, or constant use.

- How to Help It Last: Touch up chips or scratches quickly to avoid further damage.

Epoxy Coatings

- How Long They Last: Typically 5–15 years.

- What Makes a Difference: These work great for things like floors or metal surfaces but don’t do well with a lot of UV exposure. They’re best for indoor or controlled environments.

- How to Help It Last: Protect it from heavy impact and clean up any spills right away.

Anodized Coatings

- How Long They Last: Usually 20–30 years, especially on aluminum.

- What Makes a Difference: They’re tough against corrosion but can fade over time in areas with a lot of sunlight.

- How to Help It Last: Regular cleaning keeps it looking good and prevents stains from setting in.

Galvanized Coatings

- How Long They Last: 30–70 years, depending on how thick the coating is and where it’s used.

- What Makes a Difference: These are great for steel or iron to keep rust away. They hold up well in most conditions but need protection from deep scratches or dents.

- How to Help It Last: If the coating gets damaged, repair it as soon as possible to prevent rust from spreading.

What Can Shorten the Life of a Coating?

Things like extreme sun, salty air, heavy abrasion, or constant exposure to chemicals can break down a coating faster. Surfaces that see a lot of traffic or use—like floors, outdoor structures, or machinery—may need extra attention to keep them in good shape.

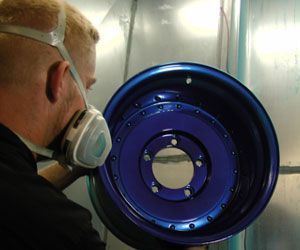

With a little care, coatings can last far beyond their expected lifespan. Simple steps like cleaning regularly and fixing damage early can make a huge difference. If you’re considering a custom coating, like those from Full Blown Coatings , we’ll help you choose the right finish and give you tips to make sure it stands the test of time.

The post What is the life expectancy of a coating? appeared first on Full Blown Coatings.