How to Preserve the Life of Iron Fences

Metal, specifically iron, is one of the strongest types of materials that you can use for your fence and gate. However, one issue that comes with iron fences is the question of durability. For all of the strength that iron has, corrosion and rust feel like an inevitability. This doesn’t have to be the case, though. There are preventative measures and specific maintenance routines that you can follow to drastically expand the lifespan of your iron fence. Here are some key methods to help you do so…

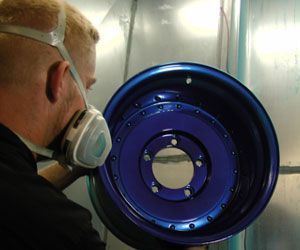

Cover with Powder Coating

Rather than painting your iron fence, opt to powder coat it in the color that you want. Powder coating creates a more even surface that protects the iron from moisture and other elements. In addition to protecting the integrity of the iron and preventing corrosion, powder coating also lasts longer than paint, creates a more vibrant color, and is far more environmentally friendly.

Best of all, a professionally-applied powder coat can last for many years and can be reapplied when damaged. This means that powder coating can practically indefinitely help expand the lifespan of your iron fence.

Use Corrosion Inhibitors

A corrosion inhibitor is a specialized chemical that adheres to the surface of metal, creating a protective film that keeps corrosion from occurring. They are incredibly effective at reducing the effect of moisture and preventing rust. This is a great option for individuals who want to keep the visual texture of iron with their fencing since the thin application of corrosion inhibitors can preserve the visibility of the metal material underneath it.

Routinely Wax

Maybe once a season, purchase some specialized protective wax for wrought iron fences and clean and wax the entire length of your fence. To do this, first, take a spray bottle and fill it with a bit of soap and a lot of water, then spray and srub each section of the fence with a sponge. After you wash a section, dry it off with a towel.

After washing apply a thin coat of wax on each section of the fence. This wax not only protects the iron from the elements but also helps preserve the powder coat and paint job too.

Limit Contact with Greenery

This is ultimately a landscaping decision, but if you are very concerned with the lifespan of your iron fence, try to keep plants, trees, and other greenery back several feet from the fence. The primary reason, by far, that corrosion occurs on iron fences is because of moisture. Shrubs and trees tend to gather dew over the night, which then drips off in the morning. If you subject your fence to this every day, then it inherently increases the corrosion process.

The post How to Preserve the Life of Iron Fences appeared first on Full Blown Coatings.